Injection de propane dans les fours d'aciéries

DÉTAILS DU PROJET

Concept et études détaillées pour la mise à niveau des installations de fours dans une aciérie, afin d'avoir une source d'énergie alternative composée d'un mélange de vapeur de PROPANE & AIR (Gaz Naturel Synthétique - GNS) en substitution du gaz naturel (GN).

GENERAL

- Période : 2023

- Localisation : Châtelet, Belgique

- Client : Aperam

SERVICES

Le contrat a inclus une étude de faisabilité avec plusieurs options et la conception détaillée de la solution sélectionnée avec GNS. La conception détaillée comprenait tous les dessins et spécifications pour les processus, la tuyauterie, le génie civil, la mécanique, l'instrumentation et l'électricité.

DESCRIPTION

L'installation disposera d'un réseau séparé de production de propane/GNS avec deux points d'injection dans le réseau GN existant fournissant du gaz aux fours. Afin de conserver les mêmes brûleurs, le GNS doit avoir le même indice WOBBE (capacité calorifique) que le GN. Une extension du réseau de lutte contre l'incendie et du réseau d'approvisionnement en air a également été planifiée.

Le réseau propane/GNS est principalement composé de :

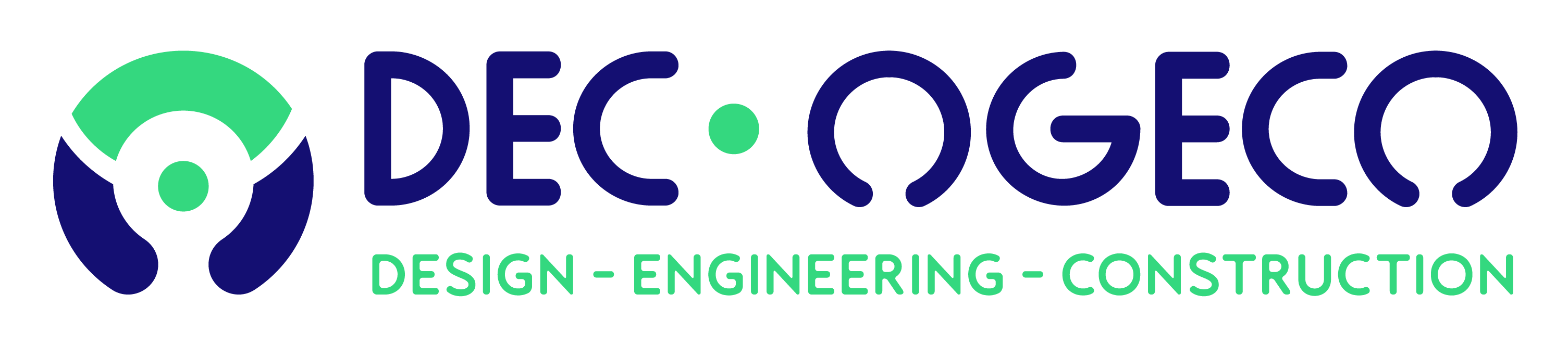

- Deux réservoirs de stockage de propane (deux réservoirs horizontaux montés de 175m³ chacun) ;

- Une zone de déchargement de camions ;

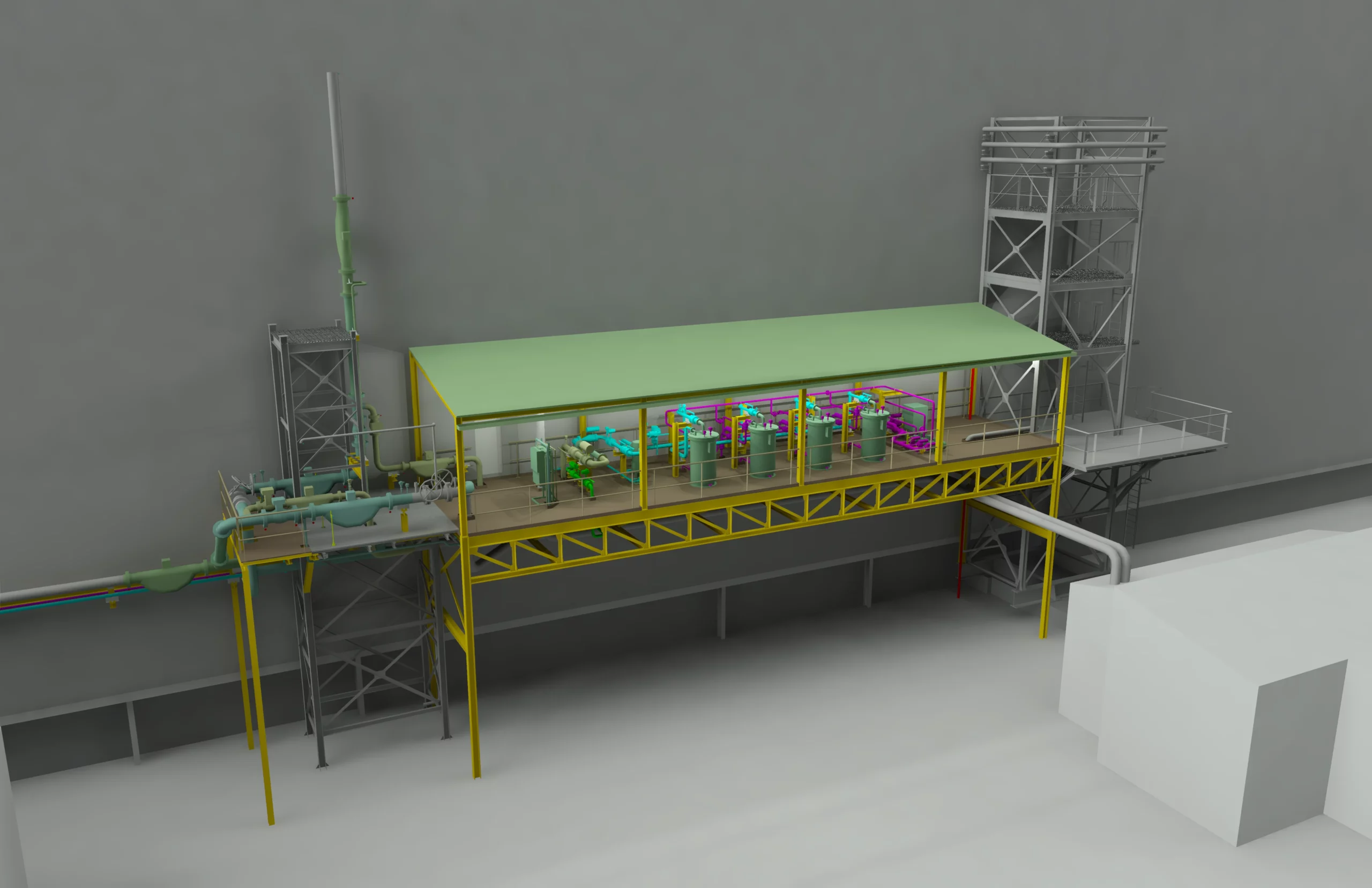

- Une station de pompage (2 pompes et 1 compresseur) ;

- Des installations de production de GNS (mélange d'air et de propane) ;

- 2 points d'injection de GNS dans le réseau de gaz naturel ;

- Instrumentation pour les réservoirs de processus et le réseau avec transmission au système de supervision garantissant une gestion appropriée des stocks.